Product Overview

- Rugged construction, capable of withstanding the abuse of the production environment

- Aluminum frame, hard coat anodized and Teflon coated

- Precision ground, 303 stainless steel coating bars for highly accurate cross web coating

- Set the gap quickly with two feeler gauge sets, included with the machine

- Reservoir capacity up to 125 mL

- Reservoir is capable of maintaining temperatures up to 400°F (204°C)

- Coating range capable of producing 25 gsm to 1,500 gsm samples

- Produce samples of unlimited length from 3" (7 cm) to 12" (30 cm) in width

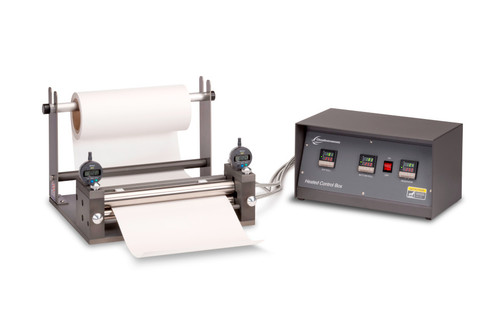

- 500-watt heating rods provide heating capacity to the reservoir and two coating bars

- J-type thermocouple is an integral part of each heating rod

- Reservoir and coating bar temperatures are accurately maintained by individual digital PID controllers

- Temperature controllers, heating elements and electronics are housed in a separate steel enclosure

- Heating elements connect to the control box with individual 36" (1 m) stainless steel armored cables

- Controllers are capable of maintaining temperatures to a tolerance of +/- 2°F (1°C)

- Quickly disassembles with a minimum of parts for easy cleaning *Unwind stands are capable of holding roll stock up to 12" (30 cm) diameter by 12" wide (30 cm)

- Steel base assembly firmly supports the coating head and unwind stand

- Adjustable Teflon side dams allow for coating control from 1/2" to 12" in width

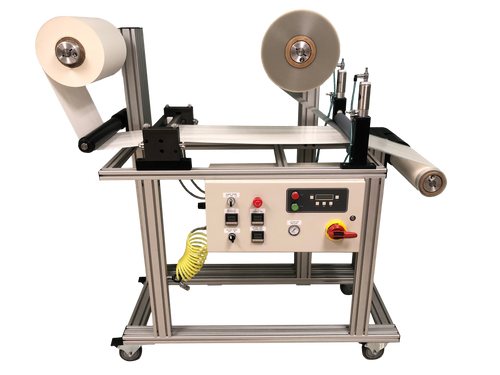

- Friction type brake unwinds on both liner and face material

- Simple pivot mechanism on unwinds allow for basic web alignment

- Top and bottom laminator rolls are 2" (5 cm) diameter by 24" (61 cm) face width

- Top and bottom laminator rolls have a steel core and are covered with 80 durometer silicone rubber

- Bottom laminator roll is driven, top roll idles

- Requires compressed air - max pressure 90 PSI (6 bar)

- Air pressure is adjustable for differing levels of laminating pressure

- Laminating pressure (LP) can be approximated using the following formula: LP = (3.4 x line pressure) / sample width Flow controls are included on both laminator cylinders to allow for smooth, safe operation

- Safety features include appropriate guarding and an emergency stop switch

- Length of lamination can be measured

- Digital controls to control speed, unit of measure and jog functions

- Variable speed motor allows laminating speeds from 1.0-12.5 fpm (30-375 cm/m)

- Standard input voltage - 120 VAC (50/60hz)

Accessories

- Manual windup station

- Laminator gap adjustment

- Bull nose coating bar

- Wire wound coating bars (Mayer)

- Pattern coating inserts

- Release paper (roll)

- Polyester (roll)

Options

- Inpute voltage– 220 VAC (50 Hz)

- Custom coater widths available

- PSTC and TLMI testing manuals and videos

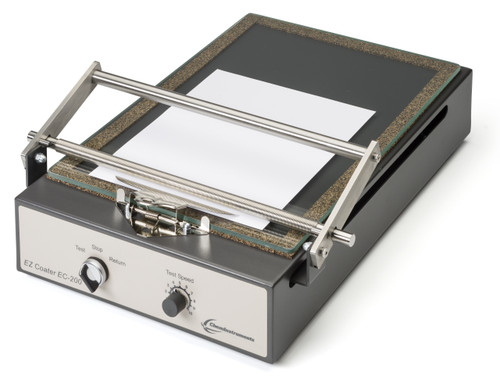

The Hot Melt Laboratory Coater / Laminator is a precision laboratory bench top hot melt coating and laminating system capable of producing coated and laminated samples of hot melt adhesives on foils, films, papers and other web based materials. Lab scale simulations of production processes can be easily set up and studied. The ability of setting a specific gap and then being able to change the pull speed with the laminator allows you to dial in a specific coat weight. This feature benefits the development of hot melt adhesive systems for future production. The Hot Melt Laboratory Coater / Laminator includes: brake, unwind stand, and simple guiding system - 120 or 240 Volt units available.