Product Overview

- Rugged construction, capable of withstanding the abuse of the production environment

- Aluminum frame, hard coat anodized and Teflon coated

- Precision ground, 303 stainless steel coating bars for highly accurate cross web coating

- Set the gap quickly with two digital feeler gauge sets, included with the machine

- Reservoir capacity up to 125 mL

- Reservoir is capable of maintaining temperatures up to 400°F (204°C)

- Coating range capable of producing 25 gsm to 1,500 gsm samples

- Produce samples of unlimited length from 3" (7 cm) to 12" (30 cm) in width

- 500-watt heating rods provide heating capacity to the reservoir and two coating bars

- J-type thermocouple is an integral part of each heating rod

- Reservoir and coating bar temperatures are accurately maintained by individual digital PID controllers

- Temperature controllers, heating elements and electronics are housed in a separate steel enclosure

- Heating elements connect to the control box with individual 36" (1 m) stainless steel armored cables

- Controllers are capable of maintaining temperatures to a tolerance of +/- 2°F (1°C)

- Quickly disassembles with a minimum of parts for easy cleaning *Unwinds are capable of holding roll stock up to 12" (30 cm) diameter by 12" wide (30 cm)

- Steel base assembly firmly supports the coating head and unwind stand

- Adjustable Teflon side dams allow for coating control from 1/2" to 12" in width

- Top and bottom laminator rolls are 2" (5 cm) diameter by 24" (61 cm) face width

- Top and bottom laminator rolls have a steel core and are covered with 80 durometer silicone rubber

- Bottom laminator roll is driven, top roll idles

- Requires compressed air - max pressure 90 PSI (6 bar)

- Air pressure is adjustable for differing levels of laminating pressure

- Laminating pressure (LP) can be approximated using the following formula: LP = (3.4 x line pressure) / sample width Flow controls are included on both laminator cylinders to allow for smooth, safe operation

- Safety features include appropriate guarding and an emergency stop switch

- Length of lamination can be measured

- Digital controls to control speed, unit of measure and jog functions

- Variable speed motor allows laminating speeds from 1.0-12.5 fpm (30-375 cm/m)

- Standard input voltage - 120 VAC / 1 Phase / 20 amp breaker or 240 VAC / 1 phase / 15 amp breaker

Key Features

Unwinding Roll #1:

- Cantilevered design for easy access and operation

- Air-powered shaft with 3" core, accommodating up to a 13" maximum web width

- Unwind includes a variable force, 25-pound, magnetic braking module for precise tension control

- Substrate capacity: 3" core, 13" maximum web width, 9" maximum outer diameter

- Integrated into the Customized Cart for optimized mobility and space utilization

Idler Roll:

- Cantilevered design for efficient substrate leading into the Hot Melt Coating nip

- Adjustable height to ensure precise alignment and coating application

- 3" outer diameter by 13" wide aluminum roller with polished and anodized surface for smooth coating.

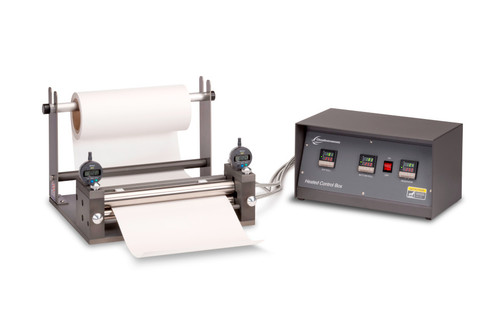

Hot Melt Coater:

- Utilizes the standard UC-200 coating head designed for 13" wide web substrates and 12” wide coatings

- Heating controls integrated into the main control cabinet

- Frame rail mounted for stability and rigidity during operation

- Offers operational specifications similar to the standard unit (UC-200)

Unwinding Roll #2:

- Cantilevered design for easy access and setup

- Air-powered shaft with 3" core, suitable for up to 13" maximum web width

- Unwind equipped with a variable force, 25-pound, magnetic braking module for precise tension control

- Substrate capacity: 3" core, 13" maximum web width, 9" maximum outer diameter

- Integrated into the Customized Cart for optimized mobility and space utilization

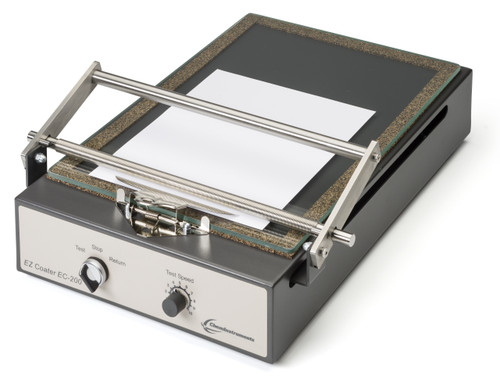

Laminator:

- Based on the standard LL-100 benchtop laminator designed for 13" wide web substrates

- Room temperature laminator for versatile laminating applications

- Top and bottom rolls made of 2" silicone rubber covered material with 80 durometer for consistent lamination

- Independent variable speed motor for flexible control over lamination speed

- Speed range of 1.0-12.5 fpm (30-375 cm/m) for various production needs

- Laminator controls integrated into the main control cabinet

- Frame rail mounted for stability and rigidity during operation

Rewind:

- Cantilevered design for easy access and winding operations

- Air-powered shaft with 3" core, supporting up to 13" maximum web width

- Rewind includes a variable force, 25-pound, magnetic clutching module for precise tension control

- Independent set-speed motor for flexible control over the rewinding process

- Located just past the Laminating nip for ease of access and efficient winding

- Adjustable height to accommodate various winding angles from the Laminator nip

Customized Cart:

- Custom-designed cart equipped with locking swivel wheels for easy mobility and positioning

- Frame rails offer flexibility in locating the various components for optimal arrangement

- Compact dimensions, not exceeding 48” long x 32” deep x 57” high, ensuring space efficiency

- Customized control cabinet designed to hold all required controls, including electric and pneumatic

The Mini-Coater is a versatile and compact coating system designed for precise and uniform application of hot melt coatings and lamination on small-scale substrates. This customized cart-based machine combines an Unwinding Roll #1, Idler Roll, Hot Melt Coater, Unwinding Roll #2, Laminator, and Rewind to provide a comprehensive coating and laminating solution. The Mini-Coater is ideal for small-scale coating and laminating applications in research, development, and small-batch production environments. Its precise and user-friendly design ensures consistent results for various substrates and coating materials.